Máquina de reciclagem LDPE

- Pacote:

- Carregado em paletes de madeira, coberto por filmes plásticos

- marca:

- Polystar

- Lugar de origem:

- Taiwan

Informação básica

Modelo: HNT-V

Descrição do produto

Máquina de reciclagem LDPE

Máquina de reciclagem LDPE

| Recycling Material | |

|

|

| PE/PP Film Roll Bags Film Scraps Bubble Film Film Sheet | |

|

|

| Raffia Nonwoven Flakes Strech Film Garbage Bag Washed Flakes |

Máquina de reciclagem LDPE

| Post-Industrial Waste | ||

| ||

Blown and Cast Film Producers |

Raffia & Woven | Rigid Regrind |

|

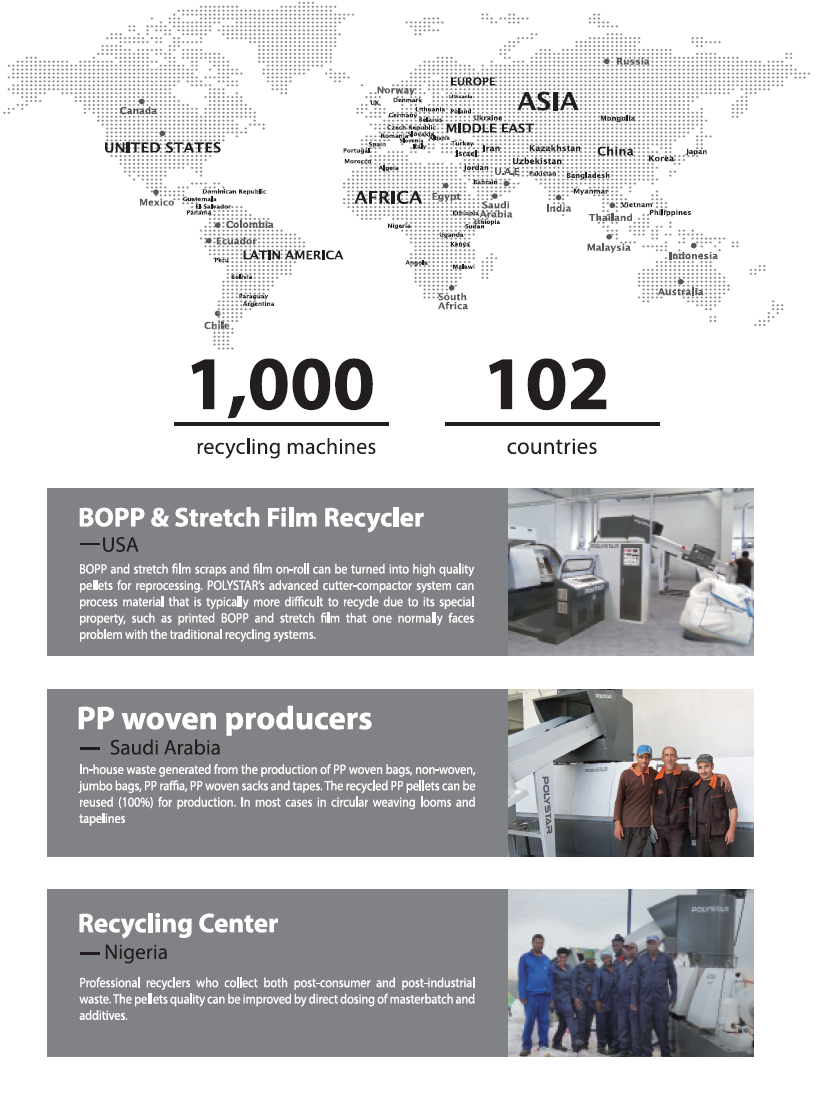

HDPE, LDPE, PP, shirnk, stretch film, BOPP,CPP, OPP leftover waste of edge trim from blown film in the format of scraps(T-shirt bags cut-offs from bag making processes), complete film rolls and sheet can be eddiciently recycled in a simple process. The high quality, uniformed sized recycled pellets are almost like virgin material which can be put directly back into the film production line. |

In-house waste generated from the production of PP woven bags, non-woven, jumbo bags, PP raffia PP woveb sacks and tapes. The recycled PP pellets can be reused (100%) for production, in most cases in circular weaving looms and tapelines. |

Pre-crushed, heavy rigid regrind scaps such as bottles, pipes, containers and lumps in the form of granules. Applicable materials are mailny HDPE, LDPE, PP, PA, PC, PU, ABS and others |

| Simple in Design, Flexible in Operation | ||

|

- One-step direct technology with cutting + extrusion +pelletizing - Very easy to install, operate and perform maintenance - Fast change between different types of material | ||

|

POLYSTAR’s Repro-Flex is designed for the reprocessing of polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. This cutter integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a highly productive rate. |

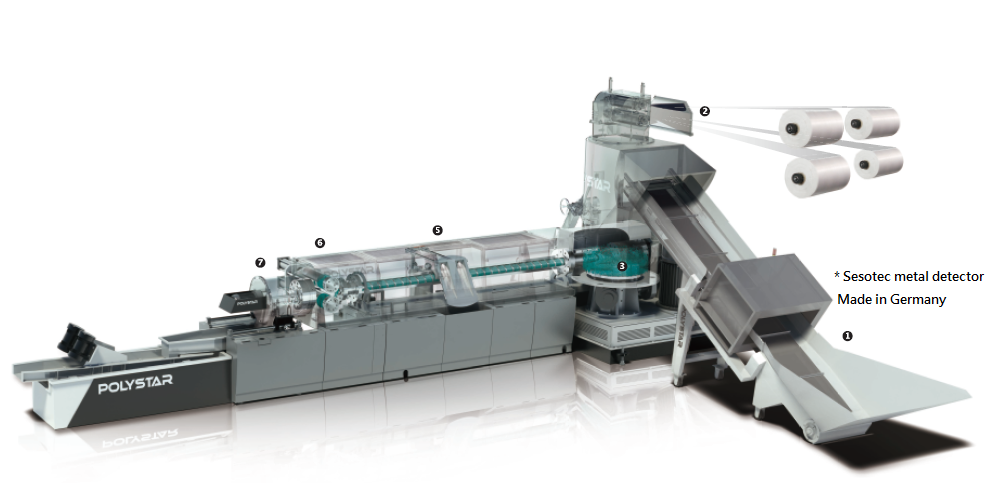

| How Repro-Flex Recycling Machine Works | |

|

1 & 2 - Feeding Feeding of scraps is easy, flexible and autimatically controlled. Film-on0rolls can be fed with nip roller feeder. |

|

3- Cutting & Compacting Very fast and stable feeding from the compactor directly into the extruder |

|

4- Additive feeder Color master batch and CaCO3 compunds (in pellet form) can be added during the recycling process |

|

5- Double degassing Able to process both printed and non-printed material |

|

6- Filtration Filter with dual channel system for non-stop operation and reduces machine down time

|

|

7- Die face pelletizing Produces high quality plastic pellets for reprocessing |

Máquina de reciclagem LDPE

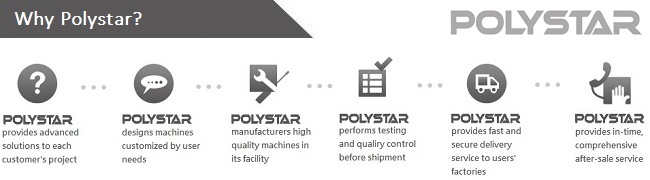

Site POLYSTAR:

Grupo de Produto : Máquina De Reciclagem De Plástico > Máquina de Reciclagem de Compactador de Cortador

Premium Related Products